Carbon neutrality

Carbon neutrality: Products, processes and partnerships for the planet

From the introduction of eco-responsible specialty fibers to investment in production sites designed to become carbon neutral, we have passed a number of important milestones in 2021 that move us closer to creating a net-zero business by 2050 at the latest.

When we set a reduction target of 50 percent by 2030, and communicated our vision to be carbon neutral by 2050, we knew that achieving it would take unwavering commitment and sustained action within each of our core strategic areas.

carbon emissions

per ton of product by 2030

Since making our commitment, new initiatives have emerged and early milestones have been reached. With these initial successes, we celebrate the ways our disciplined efforts have been rewarded with proven outcomes that are contributing to the necessary change to the textile, fashion and nonwoven industries.

Closing the production loop for eco-responsible fibers

We made a strategic commitment to reduce our carbon emissions per ton of product by 50 percent by 2030. In September, while celebrating the one-year launch of our carbon-zero TENCEL™ fibers, we announced its expansion to REFIBRA™ technology. This process involves upcycling cotton scraps into pulp, a percentage of which is then combined with virgin dissolving wood pulp to produce high quality TENCEL™ lyocell fibers. This is a huge step towards our 2030 target.

This was followed in June 2021 by the launch of the first CO2 neutral fibers on the global nonwovens market under the VEOCEL™ brand. Both, CO2 neutral VEOCEL™ fibers and carbon-zero TENCEL™ fibers, have been certified as CarbonNeutral® products in accordance with the CarbonNeutral Protocol – the leading global framework for carbon neutrality.

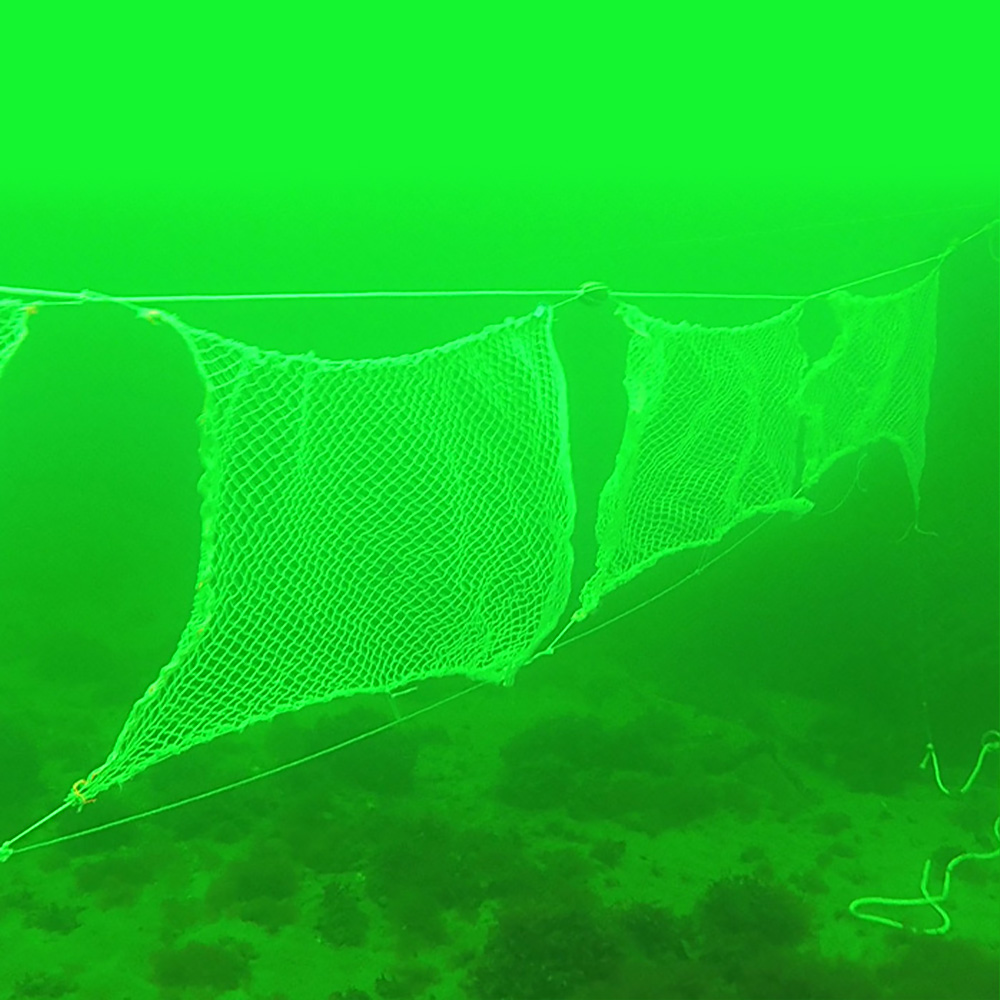

Further to this, the Scripps Institution of Oceanography at the University of California confirmed that VEOCEL™ lyocell fibers, along with other cellulosic wood-based fibers, are fully biodegradable and can decompose in sea water within 30 days.

Investing in carbon neutral production sites

investment in CO2 neutral production sites

We continue to increase energy efficiency at our existing locations and seek opportunities to use renewable sources or sources with lower carbon emissions. Planning began in 2021 on a ground-mounted photovoltaic plant at the Lenzing (Austria) site. It is the largest of its kind in Upper Austria. In addition to this, the world’s largest lyocell production facility in Prachinburi (Thailand) will harness 100 percent biogenic energy when production starts in early 2022. Construction work has progressed well, as has development of our pulp mill in Brazil. This is set to produce 500,000 tons of dissolving wood pulp annually and generate an excess of green energy that will feed Brazil’s national grid.

We continue to invest in the improved energy efficiency of our production process at all Lenzing sites.

Our award winning Web Technology transforms botanic wood pulp into nonwoven fabric.

The pioneering technology creates nonwoven fabric with 100 percent continuous lyocell filament.

We’ve also secured renewable energy at our Alabama site in the US and committed to invest more than EUR 200 mn into transforming sites in Nanjing (China) and Purwakarta (Indonesia). The latter will contribute to the reduction or elimination of fossil-based energy consumption on each site, reducing carbon emissions regionally in Asia by 320,000 tons compared to our 2017 output.

Maintaining focus on every aspect of our carbon-neutral vision means reducing our use of all resources, including water. We have therefore invested in new state-of-the-art wastewater treatment at our Grimsby (United Kingdom) site, in line with our plan to reduce wastewater emissions by 2022. Once installation is complete, we will have biological treatment plants at every Lenzing site.

Reducing our own impact is one thing, but we also need to work with customers and partners to help them reduce their impact too.”

Krishna Manda

Vice President, Corporate Sustainability

We have also delivered unprecedented traceability across supply chains with the extension of fiber identification technology to all TENCEL™ branded lyocell and modal fibers, as well as VEOCEL™ branded fibers. Further to this, we completed the full rollout of value chain track and traceability enabled by a cloud platform. This delivers end-to-end transparency which gives our customers the confidence that they’re working with Lenzing fibers.

COVID-19 highlights need for carbon neutrality

“The pandemic has shown the world what is not working well in society,” Krishna continued. “If a virus can cause the collapse of the global economy, imagine what could happen when the climate finally collapses too. We have a responsibility as a producer to look at the challenges presented by the pandemic through the lens of climate change and the circular economy.”

“We need to cater for the growing population while tackling climate challenges. Achieving net-zero carbon emissions is a clear solution, and our goal in partnership with Södra is to recycle 25,000 tons of textile waste per year by 2025, which is something like one hundred million t-shirts. We don’t yet have the infrastructure in place, so we must keep asking what needs to change about the way we work, and how we can find industrial-scale solutions to industry-wide problems. Our vision and partnerships will help us to achieve this.”