Specialty fiber is the future

Consumers confirm specialty fiber is future of fashion and beauty

Market demand for specialty fibers has risen so much over the past two years, it has provided confirmation that our sustainably produced cellulosic fibers are critical to the future success of the fashion and textile industry. They are also pivotal to the nonwovens industry after COVID-19 increased the use of hygiene products.

With our specialty fibers, we provide the industry with sustainable solutions right at the beginning of the product life cycle.”

Florian Heubrandner

Vice President, Global Textiles Business

“It has been an exceptional year for our specialty fibers,” said Florian Heubrandner, Vice President, Global Textiles Business. “We have seen strong demand for all of them, even while we struggled through the continuing COVID-19 crisis. We were sold out during the whole of 2021, much like we were at the end of 2020, right at the height of the pandemic. This definitely reflects a consumer desire for sustainable fashion.”

Answering the call of environmental innovation

Both the textile and the nonwovens industries are hungry for innovation when it comes to the eco-responsible production of fibers. “The fact that our fibers are biodegradable is a real winner,” added Florian. “You can wash them, wear them and throw them away without worrying that they will shed microplastics. Dig a hole in your garden, bury a t-shirt made entirely out of our fiber, and in several weeks it is gone.”

From production to partners to people

Fashion brands and textile mills are keen to work with our carbon zero TENCEL™ Lyocell fibers, especially after we expanded it with our REFIBRA™ technology in September 2021. This is a circular production process of upcycling a percentage of textiles that would otherwise be sent to landfill. It is also one of many innovations we have worked hard to promote as we have moved in and out of lockdown across different countries at different times. “Keeping our brands at the forefront of people’s minds has been critical in the aftermath of COVID-19,” Florian continued.

“We have brought new fibers to market that physically look the same but have different properties, so we have needed to actively raise awareness of the products’ advantages. We have held webinars and conferences online. We have visited customers and partners at their premises during the months when lockdown was lifted. We have also attended industry fairs where possible.”

Timeless denim style brought up to date with Lenzing technology

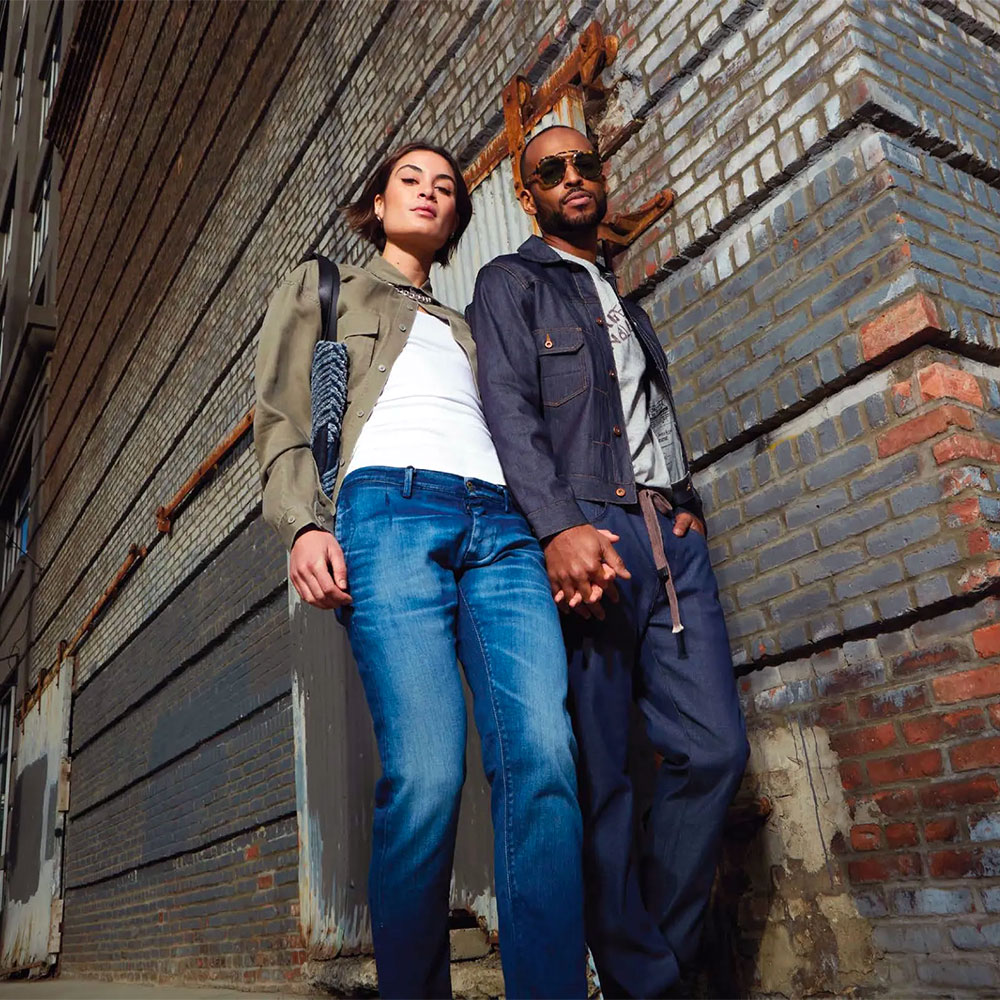

Collaborations around the globe have seen TENCEL™ branded lyocell and modal fibers used in everything from lingerie to home furnishings. While our brand and retail partners respond to trends that come and go, we know that denim wear will always be in demand. Traditionally a ressource-intense process that uses high volumes of water, the eco-credentials of denim production have benefited from TENCEL™ branded fibers.

In February 2021, we unveiled TENCEL™ modal fiber with Indigo Color technology for the denim industry. Our innovation applies indigo pigment directly into the modal fibers through a one-step spun-dying process, which sets a new benchmark for indigo application by using significantly less water.

The market appeal of the TENCEL™ brand was also apparent in October 2021 when leading denim brand JACK & JONES incorporated 38 percent of the TENCEL™ branded fibers into its latest range. “Our team is delighted to partner with Lenzing so we can bring to life more sustainable products that are also comfortable and of high quality. This allows us to showcase our unwavering commitment to enhancing sustainability in the fashion world,” said Mikkel Hochrein Albrektsen, Creative Buying Manager of JACK & JONES.

We also launched matte TENCEL™ lyocell fibers in October 2021 after retailers told us that consumers want the option to choose less shiny fabrics. We therefore created a fiber that reduces the shine of conventional lyocell denim but maintains its eco-credentials. “Innovation is at the core of what we do,” said Florian. “By upending traditional manufacturing processes and implementing our pioneering fiber technology, we’re helping denim brands evolve so they can remain competitive within the industry.”

Sustained investment in sustainably produced fibers

With demand for specialty fibers on the rise, and our optimism that this upward trend will continue, investment in production capacity is needed. Construction has been ongoing since 2019 on a new lyocell plant in Thailand. We have also invested in production sites in Indonesia and China. “With our specialty fibers, we provide the industry with eco-responsible solutions right at the beginning of the product life cycle,” Florian added. “In sharing our fiber innovations, we hope that they become mainstream practices. We will continue to work with partners and fashion brands to reduce the carbon footprint of the entire value chain, keeping in mind the ultimate goal of a carbon neutral textile industry.”